For the primary time in India, a real-time, cloud-based sensor expertise system is getting used to observe street floor high quality inspection throughout lively development.

Along with Kistler, a specialist in dynamic measurement expertise, and RTDT Laboratories, an ETH Zurich spin-off, the Uttar Pradesh Expressways Industrial Improvement Authority is equipping the formidable Ganga Expressway mission with an clever end-to-end system that detects street floor deviations as they happen. This reduces the necessity for rework, cuts prices, and improves long-term street security, and helps monitoring and upkeep all through the street’s operational life.

Following its preliminary use on the Ganga Expressway, the system is now being adopted on a number of different Indian expressways.

Spanning 594 kilometers throughout Uttar Pradesh, India, the Ganga Expressway is designed to attach tens of millions of individuals and enhance the regional economic system. However alongside the sheer scale of the mission, one of the crucial formidable street infrastructure tasks in Asia, comes a essential problem: guaranteeing development high quality with out slowing down progress.

Though street high quality assessments have historically been carried out throughout development in India, these strategies required vital handbook effort and lacked the pace and precision of built-in, sensor-based methods.

The Uttar Pradesh Expressways Industrial Improvement Authority (UPEIDA) was looking for a extra proactive and data-driven method for a mission of this magnitude: a system able to detecting street high quality deviations close to actual time, straight on-site throughout lively development. The answer additionally wants to offer goal assessments of journey consolation and security primarily based on worldwide requirements, whereas supporting long-term upkeep planning.

To satisfy these necessities, Kistler delivered a whole sensor-to-cloud street high quality evaluation system along with RTDT Laboratories AG – a spin-off of ETH Zurich. This expertise integrates superior in-vehicle measurements, native knowledge processing, cloud analytics, and visible reporting.

Mounted on take a look at autos, the measuring system for street floor high quality inspection makes use of high-dynamic acceleration sensors and HF-series laser top sensors to measure the street floor profile with excessive precision and spatial decision.

The HF sensors use optical triangulation with a purple laser to ship non-contact top measurements. Optoelectronic pace sensors, such because the Correvit S-Movement, are mixed with inertial measurement items to seize synchronized motion and positioning knowledge throughout every part of the roadway. These sensors present low sign delay and combine GPS and accelerometers to ship dependable positional and dynamic knowledge for every street section.

Kistler delivered a whole sensor-to-cloud street high quality evaluation system along with RTDT Laboratories AG – a spin-off of ETH Zurich

Edge computing modules then pre-process this knowledge domestically, reduce latency and scale back bandwidth earlier than securely transmitting it to the Kistler Cloud. The cloud-based analytics, developed by RTDT consider the uncooked knowledge utilizing domain-specific algorithms. This consists of calculating the roughness of a street floor utilizing the Worldwide Roughness Index (IRI) in addition to assessing journey consolation and vibration in accordance with ISO 2631.

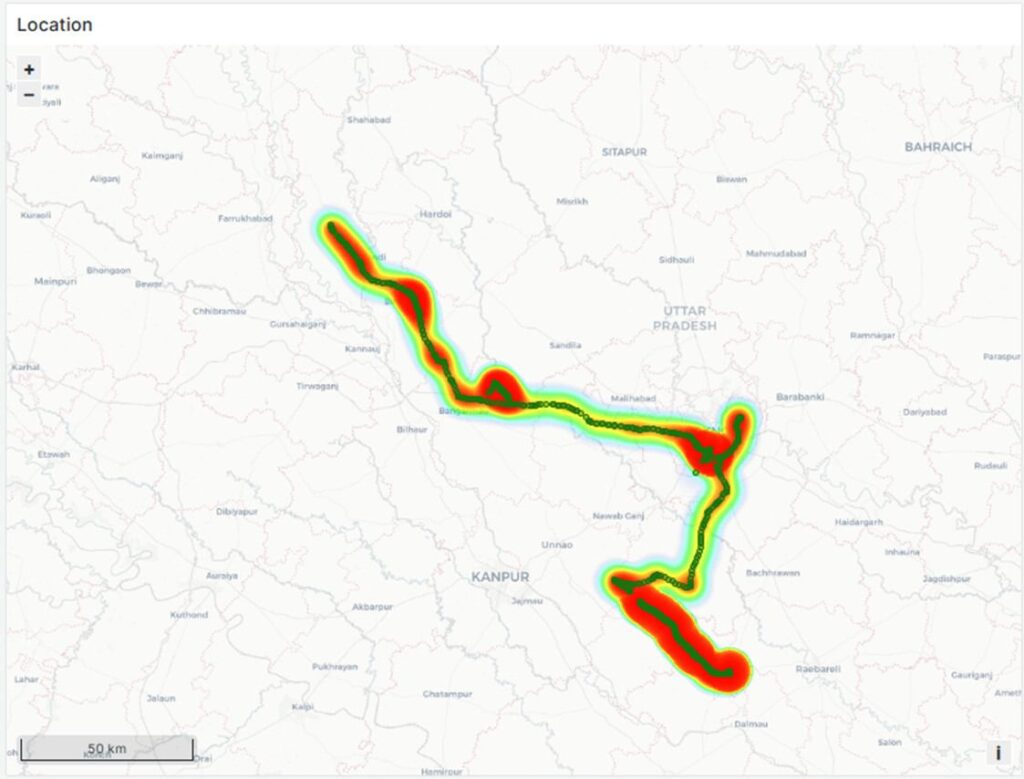

All outcomes are made accessible by an interactive, map-based dashboard. Contractors, supervisors, and authorities can use the dashboard to visualise street high quality per lane and per 100m street section, offering actionable insights in close to actual time.

Whereas the core expertise was developed in Switzerland by collaborations with ETH Zurich and RTDT Laboratories, the rollout and native adaptation of the system are managed by Kistler Devices India Pvt. Ltd. in shut coordination with native infrastructure authorities.

On the Swiss facet, Kistler’s Innovation Lab – a unit specializing in sensible companies that remodel measurement knowledge into sensible functions – coordinated Kistler’s contributions to the mission. Working carefully collectively, all companions accomplished the total implementation in simply three months, bringing collectively technical improvements from a number of domains and making the mission each a logistical success and an architectural milestone.

Highway floor high quality deviations and vibration ranges are objectively tracked and documented to assist implement security requirements and optimize development high quality at each stage. This proactive method reduces long-term upkeep prices, ensures full traceability, and stays worthwhile as soon as the street is operational. With steady monitoring, infrastructure managers can monitor floor degradation, detect rising points early, and schedule predictive upkeep. This helps protect journey high quality, uphold security requirements, and lengthen the street’s lifespan.

After its profitable implementation on the Ganga Expressway, the end-to-end sensor answer for street floor high quality evaluation from Kistler is now being deployed on different main India expressways, together with the Gorakhpur Hyperlink Expressway, Agra-Lucknow Expressway, Purvanchal Expressway, and Bundelkhand Expressway.

Photographs courtesy of Kistler